Secara garis besar Roadmap penelitian KK ABT adalah tahapan-tahapan pengembangan teknologi bioproduksi dan biokonversi untuk menjadi salah satu acuan menuju pembangunan sistem Pertanian–Bioindustri berkelanjutan di Indonesia.

A. Ruang lingkup penelitian dan pengembangan KK ABT meliputi :

Penelitian dan pengembangan proses konversi untuk menghasilkan bioproduk dengan peningkatan produktivitas tanaman sebagai sumber utama bioindustri (pangan, pakan, bahan bakar nabati, biokimiawi, serat dan lain lain). Keberlanjutan tingkat produktivitas pertanian sangat tergantung pada penataan atau pengaturan struktur organisme dalam kaitan interaksi organisme satu dengan lainnya dan khususnya dengan biota di lingkungan lahan pertanian tersebut. Oleh karena itu lingkup penelitian akan dilandasi penstrukturan proses hayati dalam suatu eksosistim yang harmonis disuatu lingkungan pertanian.

Penelitian dan pengembangan proses konversi untuk menghasilkan bioproduk dengan spesifikasi yang diinginkan. Alur konversi yang diutamakan adalah alur biological-conversion dan biochemical-conversion flows that take place at temperatures and pressures close to the environment.

B. Kegiatan Bidang Agroteknologi

The search for interest to increase capacity of lecturers in the form of an assessment of specific agricultural commodities to be developed, especially related tointegrated farmingthat utilizes resources, especially in the use of land and sunlight as effectively as possiblestratified farming).

Pengembangan laboratorium lapangan sebagai sarana untuk meningkatkan kapasitas Dosen pada KK ATB baik dalam bentuk penelitian mapun pengabdian pada masyarakat. Selain itu laboratorium lapangan juga ditujukan sebagai sarana bagi mahasiswa dalam proses pelaksanaan penelitian dan pengabdian pada masyarakat.

C. Kegiatan Bidang Teknologi Bioproduk

Penelitian dan pengembangan bioproduk yang terkait dan dilakukan KK ABT adalah proses produksi biofuels (Pure Plant Oil, Biodiesel, dan Ethanol) dan biochemicals. Salah satu teknologi yang dipatenkan di Indonesia melalui Institut Teknologi Bandung adalah teknologi produksi biodiesel terintegrasi dengan menggunakan alat kontaktor dan separator sentrifugal. Melalui Research Project: Mobile Technology for Biodiesel Production from Indonesian Resources (2011 -2015) yang didanai NWO dan KNAW Netherlands, teknologi biodiesel ini terus diuji dengan bahan baku dari bebagai sumber lipida di Indonesia. Dari berbagai tahapan penelitian dan pengembangan keandalan teknologi ini sudah teruji. Oleh karena itu dimasa mendatang penelitian dan pengembangan ditujukan kearah hulu yaitu pengembangan ketersediaan bahan baku biodiesel berupa etanol dan lipida dengan penerapan konsep biorefinery.

Peta Jalan Penelitian KK ATB

Secara garis besar peta jalan (roadmapTheroadmap of ABT research and development is the stages towards the development of a sustainable Agriculture-Bioindustry system in Indonesia that can be achieved by using the concept of biorefinery dan siklus bio-geo-kimiawi (Biogeochemical Cycles). Biorefinery is a concept of processing the entire biomass to produce various components of bio-products with the lowest possible input of energy and external materials and overall giving maximum added value to the biomass processed. An innovative and strategic scheme that should be implemented to support the sustainability of agriculture-bioindustry is the processing of biomass with the biorefinery concept, biorefinery which requires the guarantee and ease of recyclingrecycleThe return of key nutrients to the farm can increase land productivity and reduce external nutrient inputs while maintaining the harmony of plant interactions with the environment, especially with organisms that support the sustainability of the ecological system around the farm.

Under the general umbrella of platform biorefinery, some of platform specific platform possibilities that can be pursued towards integrated agro-bioindustry are:carbohydrate and protein platform” yaitu berbasis karbohidrat (padi) dan protein (hortikultura), “oil and starch platform‘oil and starch platform’ which is vegetable oil (lipids) such as castor bean, rubber seed, hazelnut seed and starch (root crops),terpenoid platformwhich is essential oil such as eucalyptus, citronella, cinnamon and frankincense andbiological conversion platform‘biological conversion platform’ which converts biological resources into high-value bioproducts using biological agents such as Trigona bee, black soldier fly (BSFL) and cattle. Spatially integrated bioindustrial development with biomass producers will increase the added value of agricultural biomass and create off-farm jobs in off-farm rural areas and help realize a sustainable agri-bioindustrial system..

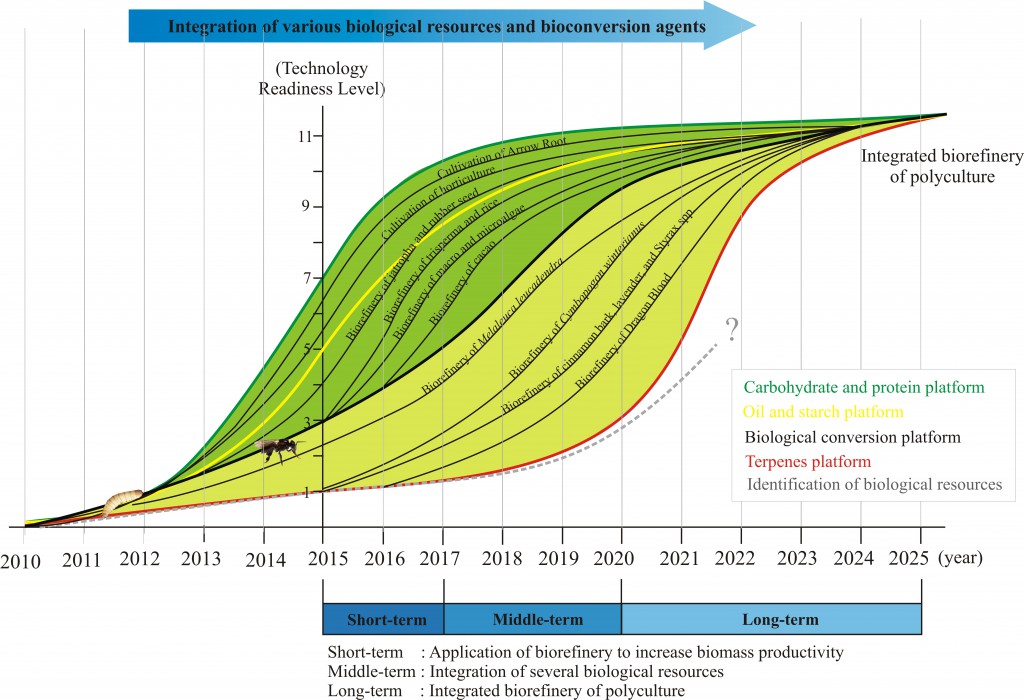

Research activities in the ATB Research Group can be divided into three stages, namely basic research, applied research and development research that refers to the Technology Readiness Level (TKT) in accordance with the SITH Strategic Plan. Figure 1 shows the road map for the development of bioproduction and bioconversion technology of various sources of primary and secondary metabolites from 2010 to 2025 follows the morphological shape of a leaf with the basic building of Oblongus which is elongated with almost parallel sides. The leaf blade reflects the bioconversion technology, while the upper leaf blade reflects the carbohydrate and protein platform and the oil and starch platform. The lower leaf blade represents the terpenes, phenolic, and nitrogen-compound platform. Road map is prepared for the next 10 years starting from 2015-2025. The establishment of the Bioengineering Study Program at SITH ITB in 2010 became the basis for the start of research and development activities of the ATB. The TKT for carbohydrate and protein platform is already at level 7 (development research), which is the demonstration of system prototypes in actual environments.

The TKT for oil and starch platform cultivation and oil and starch platform which is the validation of components/subsystems in a relevant environment. The trial production of biodiesel from rubber seeds was demonstrated in Palangkaraya in 2015 while the program to utilize hazelnut seeds to produce bioproducts using the biorefinery concept was disseminated in Jatigede in 2016. The TKT for the cultivation and processing of terpenes, phenolic, and nitrogen-compound platform is still at level 1 (basic research), where the basic principles of the technology are researched and reported. Research related to essential oil from eucalyptus has been researched and reported since 2010, while the utilization of citronella leaves to produce essential oil and other bioproducts using the biorefinery concept has been researched and reported since 2014. Other potential resources as raw materials to produce secondary metabolitesterpene, phenolic, dan nitrogen-containing compoundare still being identified, including cinnamon and frankincense, which will begin in the second semester of 2016.

The TKT for the biological conversion platform as a whole is at level 3, which is analytically and experimentally proving important concepts, functions and/or characteristics. The research developed at ATB is based on the Input-Proses-Output (IPO) concept. The inputs used are biological resources including rice and horticultural crops as well as macro and micro-algae while the output . The process used to convert inputs into outputs is a biological process that uses biological agents either plants, animals or microbes. Examples of biological agents used in biological conversion platform platforms include Trigona bees, BSFL, cows and also fungi.

In the long term, the research and development of the ATB Group does not stop at level 9 as stated in the SITH Strategy Plan document but continues to higher levels, namely levels 10 and 11. Level 10 is the integration of various biological resources and bioconversion agents in an integrated agricultural system to produce the development of a sustainable Agriculture-Bioindustry system. Level 11 is continuous improvement to increase productivity and conversion efficiency in order to achieve an integrated polyculture-biorefinery system, integrated polyculture-biorefinery namely the simultaneous cultivation of various plants and other organisms to produce various high-value bioproducts using the biorefinery.